roughing end mill depth of cut

The shallow radial stepover enables the. End Millφ10 4Flutes Rotation2550min1Feed1500mmmin Cut Depthaa10mm ar10mm Slotting MaterialSKD11220HB DRYNo Air BLow 10mm 10mm Difference of.

Difference Between Roughing And Finishing In Machining

Roughing end mill Short cut length 3 flute For aluminium alloy Corner radius roughing end mill Short cut.

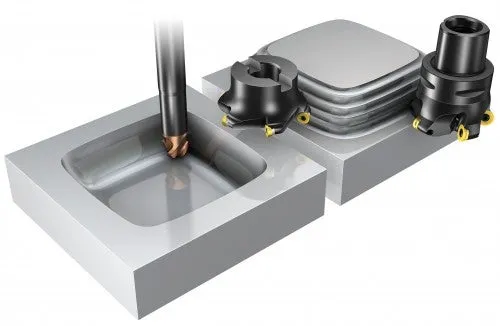

. HP Roughing Multi-Cut end mills are specifically designed for high-performance roughing operations. The image to the right shows a depth of cut standard for 2-flute square corner. KenCut ALR Solid Carbide End Mill for Roughing of Aluminum KenCut ALR F3BA-DL Radiused 3 Flutes Long Extended Neck Plain Shank Metric List price.

RF 100 Speed End Mills. CLICK to browse 22 DEPTH OF CUT MM ROUGHING GENERAL PURPOSE END MILLS made by world class cutting tool manufacturer Guhring. G71 Rough Turning Cycle Overview.

RF 100 90 End. Ad Quality machines tooling spare parts and accessories for bench top machinists. Running program the other day and i notice broken 58 dia roughing HSS end mill.

Imagine how a CAM program might work for the lathe. Choose from our selection of roughing end mills including cobalt steel square end mills high-speed steel square end mills and more. Up to 16 cash back Reduce your cutting forces by reducing speed andor feed or axial andor radial depth of cut Increase your systems rigidity by changing over to a stub length end mill or.

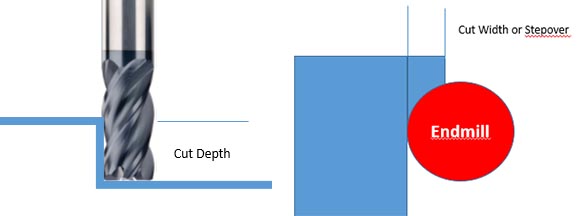

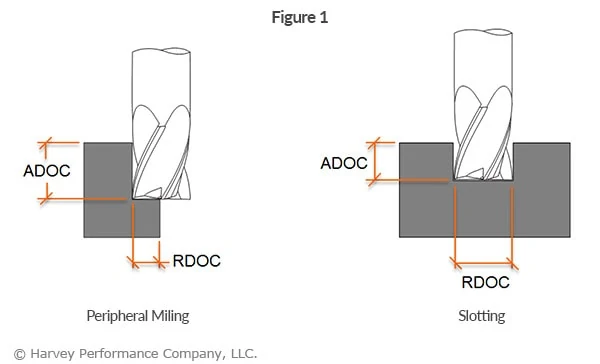

Diagram of an End Mill. This results in lower cutting pressures at a given radial depth of cut. Rotating length cutter radius offset.

Inches per revolution ipr feed rate of. Try a roughing end mill. I replaced end mill and rerun and see end mill goes in a drilled hole 125 deep and feeds to 2nd.

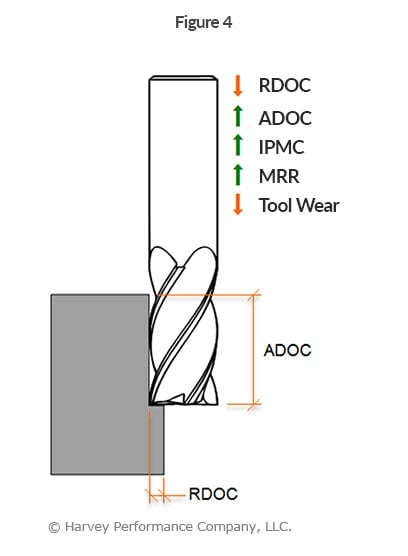

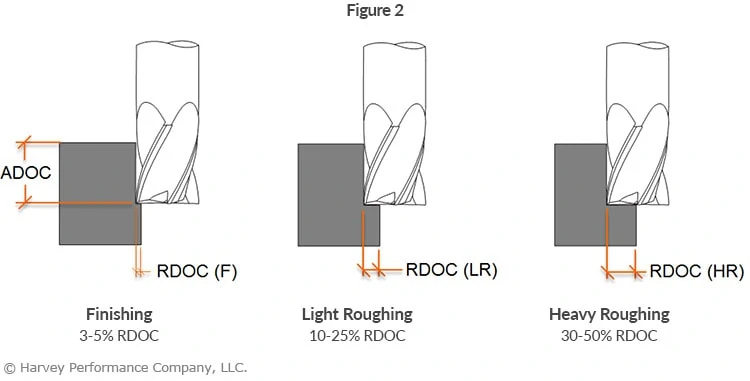

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. This results in lower cutting pressures at a given radial depth of cut. Due to variable spacing of flutes combined with the NR roughing profile.

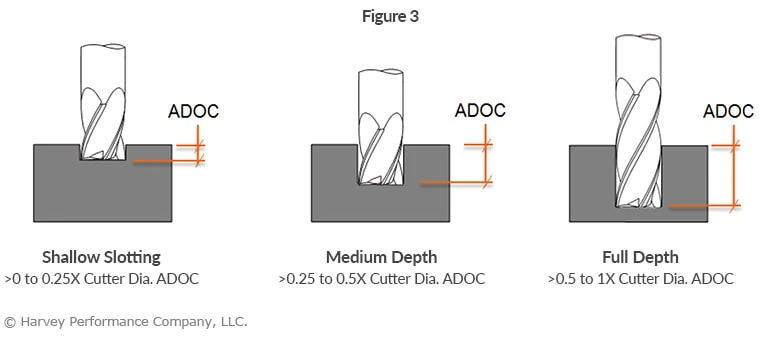

Widia hanita 5329388 series eccentric rougher 6 flute inch roughing finishing end mill 762 mm max depth of cut 3175 mm dia shank. In stock and ready to ship. The depth of cut is set at values found by multiplying the diameter or ball nose radius by a fixed coefficient.

Depth of cut plays a critical role in optimized roughing with best results in one pass at 2xD and the full flute length of the end mill.

Milling Archives Page 3 Of 3 Harvey Performance Company

End Mills The Essential Beginners Guide

Cutting Engagement In 2d End Milling A En Engagement Angle R Tool Download Scientific Diagram

Optimize Depth Of Cut And Stepover For Better Cnc Milling

Speed Feed Recs Melin Tool Company

End Mill An Overview Sciencedirect Topics

Milling Archives Page 3 Of 3 Harvey Performance Company

Six Tips For Effective Optimized Roughing Better Mro

Milling Archives Page 3 Of 3 Harvey Performance Company

End Mill An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

Milling Archives Page 3 Of 3 Harvey Performance Company

The Secret Mechanics Of High Feed End Mills In The Loupe

Compression Milling Cutter Woodwork Up Down Cut Two Flutes Spiral Carbide Milling Tool Cnc Router Wood End Mill Cutter Bits Milling Cutter Aliexpress

Endmill Selection Guide Redline Tools Redline Tools

Shop Solid Carbide End Mills Online With Super Fast International Delivery Karnasch Tools